Why Choose Us?

Range of RPD Gas Meters in Mira-Bhayandar, Maharashtra

RG-2000-EVC

RG-2000

Request a Quote

What is an RPD gas meter?

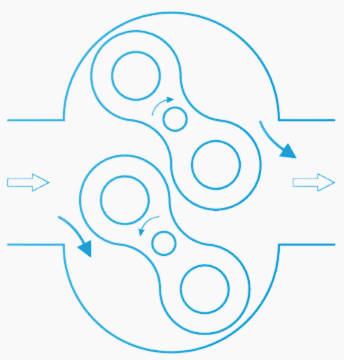

A rotary gas meter is a type of displacement gas meter that measures gas flow accurately. It operates using two impellers shaped like the number 8, which rotate within a measurement chamber. Each complete revolution of the impellers displaces a specific volume of gas from the inlet to the outlet. The total number of revolutions correlates directly to the volume of gas passed through the meter, which is displayed on a clear, direct-read counter.

Additionally, rotary gas meters can incorporate both low and high-frequency pulses, enhancing flow computation and control capabilities. This makes them an efficient choice for monitoring gas usage in various applications.

Here is how an RPD flow meter in Mira-Bhayandar works:

RPD (Rotary Positive Displacement) gas flow meters measure gas flow by using a simple yet effective mechanism. Here’s how they operate:

-

Internal Mechanism: The meter contains two rotating impellers or gears that trap a specific volume of gas as they turn. These impellers are designed to rotate smoothly and create a sealed chamber.

-

Gas Flow Measurement: As gas flows into the meter, it fills the chamber created by the rotating impellers. Each full rotation displaces a fixed volume of gas.

-

Counting Rotations: The meter counts the number of rotations of the impellers. This count directly correlates to the volume of gas passing through the meter.

-

Display and Output: The total volume is displayed on a counter or can be transmitted to a control system for monitoring and analysis.

-

Accuracy and Reliability: RPD meters are known for their accuracy across a wide range of flow rates and are particularly effective for low to medium-flow applications.

Overall, RPD gas flow meters provide a dependable solution for accurately measuring gas flow in numerous industrial applications.

Advantages of RPD gas flow meter:

-

High Accuracy: RPD meters offer precise measurements of gas flow, making them ideal for applications requiring exact data.

-

Wide Range of Flow Rates: They perform well across various flow rates, accommodating both low and moderate-flow applications.

-

Reliability: With fewer moving parts than some other types of meters, RPD meters are generally durable and have a long service life.

-

Simplicity: The design is straightforward, making installation and maintenance relatively easy.

-

Low-Pressure Drop: RPD meters maintain a low-pressure drop, which is beneficial for energy efficiency in gas systems.

-

Versatile Applications: Suitable for a variety of gases, including natural gas, biogas, and industrial gases.

Disadvantages of RPD gas flow meter:

-

Cost: RPD meters can be more expensive than other types of flow meters, which may not be ideal for all budgets.

-

Sensitivity to Gas Composition: Changes in gas composition can affect measurement accuracy, requiring recalibration or adjustment.

-

Moving Parts Wear: While durable, the moving parts can experience wear over time, leading to potential maintenance needs.

-

Not Suitable for High Flow Rates: RPD meters may not perform well in very high flow applications, where other technologies might be more appropriate.

-

Limited Functionality: Unlike some advanced flow meters, RPD meters may lack features like remote monitoring or digital integration.

Uses of RPD meters in gas measurement:

-

Natural Gas Measurement: Commonly used in residential, commercial, and industrial applications to measure natural gas consumption.

-

Biogas Applications: Employed in renewable energy projects to measure biogas generated from anaerobic digestion processes.

-

Industrial Gas Measurement: Used in manufacturing processes that rely on various industrial gases, ensuring accurate billing and usage tracking.

-

Gas Utilities: Utilized by utility companies for monitoring and billing purposes, ensuring accurate measurement for customer accounts.

-

Heating Systems: Applied in residential and commercial heating systems to monitor gas flow for boilers and furnaces.

-

Pipeline Monitoring: Implemented in gas pipelines to ensure accurate flow measurement and leak detection, enhancing safety.

-

Chemical Processing: Used in chemical plants to measure gases involved in reactions, helping to maintain process efficiency and safety.

-

Food and Beverage Industry: Employed to measure gases used in food preservation and carbonation processes.

-

HVAC Systems: Used in heating, ventilation, and air conditioning systems to monitor gas flow for optimal performance.

Application of RPD gas flow meter in different industries and processes:

-

Natural Gas Distribution: Widely used by utility companies to measure and bill residential and commercial customers for natural gas consumption.

-

Biogas Production: Applied in anaerobic digestion facilities to monitor biogas generated from organic waste, supporting renewable energy initiatives.

-

Industrial Manufacturing: Used in factories to measure gases such as hydrogen, nitrogen, and oxygen in various production processes.

-

Heating Systems: Implemented in boilers, furnaces, and water heaters to accurately monitor gas flow and optimize energy efficiency.

-

Chemical Processing: Essential for measuring gases involved in chemical reactions, ensuring precise control over production processes.

-

Food and Beverage Industry: Used to monitor gases in processes like carbonation in beverages or preservation in food packaging.

-

Pipeline Monitoring: Employed in gas pipelines for accurate flow measurement, aiding in leak detection and safety management.

-

HVAC Systems: Used to monitor gas flow in heating, ventilation, and air conditioning systems to enhance performance and energy efficiency.

-

Research and Development: Utilized in laboratories for precise gas measurement in experimental setups and research applications.

-

Power Generation: Applied in gas turbines and other power generation systems to measure fuel gas flow for efficiency and performance optimization.