Why Choose Us?

Range of Thermal Mass Flow Meters in Tumkur, Karnataka

BT-3020-G

BT-3020-X

BT-3000-V

BT-3000-G

Request a Quote

What is a Thermal Mass Flow Meter?

A Thermal mass flow meter is a specialized tool used to measure the flow rate of gases. It operates by heating the sensor in the gas stream and then calculating the cooling effect as the fluid flows past it. This temperature change allows the meter to accurately measure the mass or volumetric flow rate of gases. Thermal mass flow meters are known for being precise and causing minimal pressure drop, It makes them crucial in various industries like natural gas distribution, inert gas measurement, and HVAC systems.

Here is How a Thermal Mass Flow Meter in Tumkur works:

A thermal mass flow meter measures gas flow using heat transfer and the cooling effect. Here’s how it works, step by step:

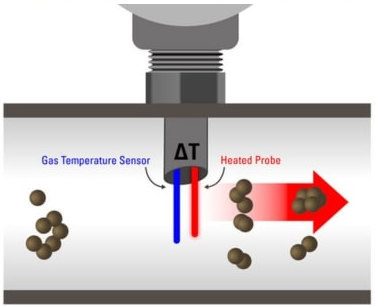

- Sensor Element: The meter contains two temperature sensors, one heated (mass flow sensor) and one unheated (reference sensor). Both sensors are placed in the path of the gas.

- Heating the Mass Flow Sensor: The heated sensor maintains a temperature higher than the gas. It’s kept warm by a small heating element.

- Measuring Temperature Difference: As gas flows past the sensors, it cools the heated one. The unheated sensor measures the gas’s actual temperature. The difference in temperature between the two sensors is directly related to the gas’s mass flow rate.

- Heat Transfer: The amount of heat carried away from the heated sensor by the gas flow causes a drop in temperature. This cooling effect is monitored, as it reflects the flow rate.

- Calculation: The meter’s electronics calculate the flow rate using the temperature difference. It applies specific algorithms or calibration data based on the characteristics of the sensors and the properties of the gas.

- Output: The calculated mass flow rate is displayed on a digital screen or transmitted as an analog or digital signal for monitoring and control purposes.

In simpler terms, think of it like this: You have one sensor that’s always warm and another that measures the real temperature of the gas. When gas flows, it cools down the warm sensor, and the difference in temperature tells you how fast the gas is moving.

Thermal mass flow meters are known for their precision and minimal pressure drop, making them valuable in industries like natural gas distribution, inert gas measurement, and HVAC systems. They provide highly accurate and reliable gas flow measurements, which is crucial for many industrial applications.

Advantages of high-temperature thermal mass flow meter:

- Thermal mass flow meters have high accuracy in gas flow measurement

- Highly suitable for low flow rates and Varying temperature/Pressure

- It has a quick response time

- It can withstand aggressive or extreme environmental conditions.

- Different types of gases can be measured by the inline thermal mass flow meters with minimal recalibration.

- The installation process is straightforward and user-friendly, Thus it ensures a smooth and hassle-free setup experience.

Uses of Thermal Mass Flow Meters in Gas Measurement:

- Natural Gas to Combustion Sources: Measuring the natural gas flow rate to combustion sources like boilers and furnaces helps determine their efficiency.

- Natural Gas Submetering: In facilities with different cost centers, submetering natural gas is used for cost allocation.

- Compressed Air: Thermal dispersion mass flow meters help determine the optimal number of compressor units needed and identify leaks in industrial compressed air systems.

- Flare Gas: Measuring and monitoring flare gas is essential to ensure proper system operation.

- Aeration Air: In wastewater treatment plants, thermal mass flow meters ensure optimal airflow for microorganisms to break down organic waste.

- Combustion Air: By accurately measuring combustion air and fuel flow, high-temperature thermal mass flow meters enable optimization of air-to-fuel ratios, achieving combustion efficiency and energy management.

Application of digital thermal mass flow meter in different industries and processes:

- Oil and Gas Industry: Here thermal mass flow meters are used to measure the flow of natural gases like natural gas, methane, and carbon dioxide.

- Waste water management: To measure the flow of gases that support purification and aeration processes.

- Power generation: In the power generation industry, It monitors combustion air to optimize air-to-fuel ratios.

- Food and Beverage Industry: In food and beverage production, It measures gases like carbon dioxide, nitrogen, oxygen, etc.

- Pharmaceutical Industry: Here the thermal mass flow meter measures the gas flows during the production of medicines.

- Chemical Industry: In the chemical industry it tracks the flow of hydrogen, nitrogen, and ammonia.

- Pulp and Paper Industry: Thermal mass flow meter monitors the stem used in drying and processing paper, to ensure optimal energy efficiency.

- Steel industry: it measures the oxygen and other gases in the blast furnaces and combustion systems to optimize fuel efficiency and reduce emissions.